Ozone in Pharma

Ozone is a valuable tool in pharmaceutical manufacturing and quality assurance,

contributing to product safety, quality, and environmental compliance.

Ozone in Pharma

Ozone is a valuable tool in pharmaceutical manufacturing and quality assurance,

contributing to product safety, quality, and environmental compliance.

Overview

Ozone is a valuable tool in pharmaceutical manufacturing and quality assurance, contributing to product safety, quality, and environmental compliance. It is essential to follow industry regulations and guidelines when using ozone in pharmaceutical processes to ensure both safety and efficacy.

Trusted by business worldwide

Products Overview

Skid Ozone Generator

The ozone generator is an electronic system which converts oxygen into ozone using the principle of corona discharge technology. High voltage electric supply applied into the ozone generator provides the energy required to form electrical arcs.

L Series Ozone Generator

The State of the Art L-series Oxygen Feed Ozone Generator is designed for high performance to work with external oxygen or dry air as feed gas to produce ozone. It has higher ozone concentration required of up to 300 gm/hr. This series is designed for high reliability, continuous running and maintenance free operation.

M Series Ozone Generator

The M-series Oxygen Integrated Ozone Generator is the most advanced systems suitable for high ozone concentration. It is ready to use straight away after installation. It comes with inbuilt oxygen unit, safety features, control panel and industrial oxygen concentrator for feed gas.

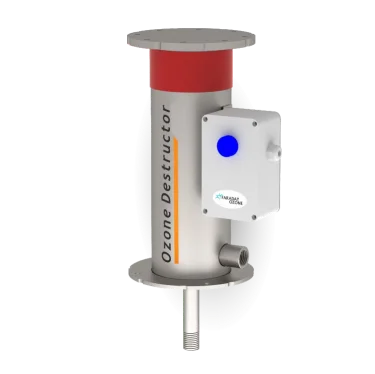

Ozone Destructor

The OD-series Ozone Destructor convert ozone gas into oxygen before releasing in the atmosphere. It works on the catalytic reaction where MnO2 is used as a catalyst and eliminate the need for complicated method.

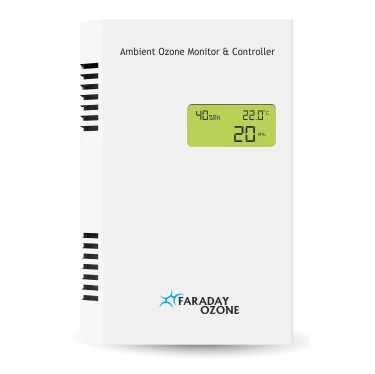

Ambient Ozone Monitor

Ambient Ozone Monitor & Controller is specially designed for continuous real-time detecting and monitoring of ambient ozone in the air. It has electrochemical ozone sensor which works quickly to measure the ozone presence accurately.

Dissolved Ozone Monitor

Ambient Ozone Monitor & Controller is specially designed for continuous real-time detecting and monitoring of ambient ozone in the air.

Questions? We’re Here to Help!

We’re available to assist you with any request you have!

Pharma Benefits of Ozone Treatment

Wastewater Treatment

Ozone treats pharmaceutical wastewater by breaking down organics, reducing COD, and ensuring compliance with environmental regulations

Preservation

Ozone extends pharmaceutical product shelf life by disinfecting packaging and preventing contamination

Cleaning and Sanitization

Ozone-based cleaning ensures contamination-free pharmaceutical production by sanitizing equipment, surfaces, and containers.

Sterilization

Ozone sterilizes pharmaceutical equipment, environments, and packaging, ensuring product safety and purity

Water Treatment

Ozone efficiently removing impurities, microorganisms, and endotoxins, upholding water quality for diverse processes.

Air Purification

Ozone generators enhance air quality in pharmaceutical facilities by eradicating airborne contaminants like microorganisms and particulates

Installation Success Stories

Explore our collection of enlightening installation success stories, exemplifying impactful product implementation

in various diverse settings and environments.

Ozone is a valuable tool in pharmaceutical manufacturing and quality assurance, contributing to product safety, quality, and environmental compliance. It is essential to follow industry regulations and guidelines when using ozone in pharmaceutical processes to ensure both safety and efficacy.

Frequently Asked Questions

How is ozone used for sterilization in pharmaceutical manufacturing?

Ozone is used to sterilize pharmaceutical equipment, production areas, and packaging materials by exposing them to ozone gas. Ozone’s powerful oxidative properties effectively kill bacteria, viruses, and fungi.

Are there safety precautions when working with ozone in pharmaceutical facilities?

Yes, safety measures include proper ventilation, ozone monitoring, and protective equipment for personnel. Ozone should be handled with care as it can be harmful when inhaled in high concentrations.

Are there regulations or guidelines governing the use of ozone in pharmaceutical applications?

Yes, pharmaceutical companies must adhere to regulatory guidelines and standards when using ozone to ensure safety, product quality, and environmental compliance.

What role does ozone play in water treatment within the pharmaceutical industry?

Ozone is used to purify and disinfect water used in pharmaceutical manufacturing processes. It can remove organic impurities, microorganisms, and endotoxins from water sources, ensuring the quality of the water.

How does ozone contribute to air purification in pharmaceutical facilities?

Ozone generators are used to improve air quality by eliminating airborne contaminants, including microorganisms and particulate matter, in pharmaceutical production areas.

Can ozone be used in pharmaceutical research and development?

Yes, ozone is used in pharmaceutical research and development for various purposes, including chemical synthesis, analytical chemistry, and oxidation studies.

Sterilization

Ozone sterilizes pharmaceutical equipment, facilities, and packaging

Quality Control

Ozone aids quality control by confirming microorganism absence in pharmaceutical products.

Research and Development

Ozone finds applications in various areas, including analytical chemistry and oxidation studies.

Air Purification

Ozone generators boost pharmaceutical facility air quality by removing contaminants.

“Nurturing Greener, Healthier and Happier World”

Why Choose Faraday?

Faraday delivers customized ozone solutions for your laundry needs. Explore our range of diverse ozone generator capacities and premium accessories, all backed by our extensive global laundry expertise. With a strong presence in the Middle East (Qatar, Egypt, Saudi Arabia, Yemen, Dubai), we guarantee a top-notch selection that transforms laundry operations.

Product Certifications

50+ Global Presence Worldwide