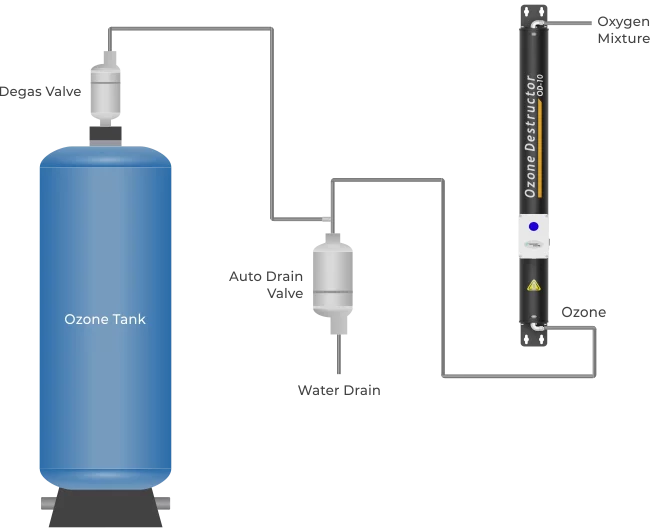

The OD-series Ozone Destructor convert ozone gas into oxygen before releasing in the atmosphere. It works on the catalytic reaction where MnO2 is used as a catalyst and eliminate the need for complicated method.

Operating Principle of Custom Indoor Air Quality Detection

Un-dissolved ozone gaseous from the application is connected at the bottom of the ozone destructor, where any moisture in the ozone gas is evaporated using heater. Once moisture in the gas is evaporated, dry ozone passes ahead and reacts with the manganese dioxide and gets converted into oxygen and released in the atmosphere.

The OD-series Ozone Destructor is the most economical and efficient method for destroying excess ozone gas after the reaction process. It guarantee to achieve 99.9% destruct efficiency for concentrations up to 50 ppm.

The OD-series Ozone Destructor is made of high grade aluminium and stainless steel with wall mount clamp that can be easily attached to an ozone contact tank, de-gas separator or other ozone contacting system to convert any excess ozone off-gas into oxygen before venting into the atmosphere. It uses an MnO2 mixture as a catalyst with for long lasting ozone decomposition potential.

- Safe way to destruct any excess ozone

- Economical technique in destroying un-dissolved ozone

- Easy to install on a new or existing ozone systems

- Best catalyst to convert ozone into oxygen faster

- High performance with lower price

Temperature Control

Some destructors incorporate temperature control features to optimize ozone decomposition and prevent overheating.

Safety Features

Ozone destructors often include safety mechanisms to shut down the unit in case of malfunctions or hazardous conditions.

Scalability

Certain models offer scalability options to accommodate different ozone volumes or concentrations.

High Efficiency

Ozone destructors efficiently convert ozone to oxygen, minimizing ozone emissions.

Technical Specifications

| Model | OD-10 | OD-20 | OD-30 | OD-40 |

|---|---|---|---|---|

| Input Power | 230 V AC 50 Hz | 230 V AC 50 Hz | 230 V AC 50 Hz | 230 V AC 50 Hz |

| Power Consumption | 60 Watts | 80 Watts | 100 Watts | 200 Watts |

| Maximum Flow Rate | 1.76 CFM | 10 CFM | 20 CFM | 30 CFM |

| Efficiency | 99.9% | 99.9% | 99.9% | 99.9% |

| Catalyst | MnO2 | MnO2 | MnO2 | MnO2 |

| Inlet / Outlet Connections | Ferrule fitting | 1/2″ BSP | 1/2″ BSP | 1/2″ BSP |

| Compatible Tubing | Teflon/SS316 | Teflon/SS316 | Teflon/SS316 | Teflon/SS316 |

| Heater | Yes | Yes | Yes | Yes |

| Humidity Range | 0 – 100% | 0 – 100% | 0 – 100% | 0 – 100% |

| Operation Modes | Continuous | Continuous | Continuous | Continuous |

| Pressure Drop | 0.1 bar | 0.1 bar | 0.1 bar | 0.1 bar |

| Material of Construction | Aluminium | SS304/316 | SS304/316 | SS304/316 |

| Dimension (DxH) | 76 x 830 mm | 101 x 355 mm | 101 x 355 mm | 101 x 355 mm |

| Weight | 8 kg | 20 kg | 30 kg | 40 kg |

Frequently Asked Questions

Global Footprint in 50+ Countries